Casting Copper for Electronics Redefining Connectivity with Mini Copper Parts

- zhongshanfuyuan

- Jul 28, 2023

- 3 min read

In the ever-evolving electronics landscape, the demand for miniaturization and enhanced connectivity has driven the industry to explore new materials and manufacturing techniques. Among these innovations, casting copper has emerged as a game-changer, enabling the creation of mini copper parts that redefine connectivity in modern electronics. This blog delves into the world of casting copper for electronics, exploring its applications, benefits, and how mini-copper parts are revolutionizing connectivity in cutting-edge technology.

Mini Copper Parts: A Marvel of Precision

In the quest for compact and powerful electronic devices, mini copper parts have emerged as marvels of precision engineering. These small yet intricate components are cast with meticulous attention to detail, enabling them to fit seamlessly into the tiniest spaces within electronic circuits.

Enhancing Connectivity: Smaller, Stronger, Faster

Mini copper parts play a crucial role in enhancing connectivity within electronic devices. Their reduced size facilitates the flow of electric currents through circuits, reducing resistance and boosting the device's overall performance. This results in faster data transmission, more efficient power delivery, and improved signal integrity.

Miniaturization of Electronics: Space Efficiency Redefined

The miniaturization of electronic devices has become a hallmark of technological progress. Mini copper parts contribute significantly to this trend, as they enable the creation of compact and space-efficient circuitry. This revolution has paved the way for sleeker, more lightweight gadgets offering advanced functionality without compromising performance.

Applications of Mini Copper Parts in Electronics

Mini copper parts have many applications in modern electronics, revolutionizing our interactions with technology.

Mobile Devices: Powering Connectivity on the Go

From smartphones to wearables, mini copper parts are at the heart of mobile devices, ensuring seamless communication and data transfer. These tiny components enable smartphones to support multiple functionalities, such as high-speed data networks, GPS, Bluetooth, and NFC, all in a compact form.

IoT and Smart Home Devices: Enabling the Connected Future

The Internet of Things (IoT) and advanced home devices rely heavily on mini copper parts to enable seamless connectivity among interconnected devices. These components, from smart speakers to smart thermostats, ensure that IoT devices smoothly communicate with each other and with cloud-based services efficiently.

Advantages of Casting Copper for Mini Parts

Design Flexibility: Tailored for Performance

Casting copper offers unparalleled design flexibility, allowing for the creation of intricate and custom-shaped mini-parts tailored for optimal performance. This adaptability ensures that mini copper parts meet different electronic applications' specific requirements, optimizing functionality and efficiency.

Excellent Electrical Conductivity: The Key to Enhanced Connectivity

Copper is renowned for its exceptional electrical conductivity, making it the ideal material for mini parts in electronic devices. Its low resistance ensures minimal signal loss and efficient power delivery, guaranteeing reliable and robust connectivity.

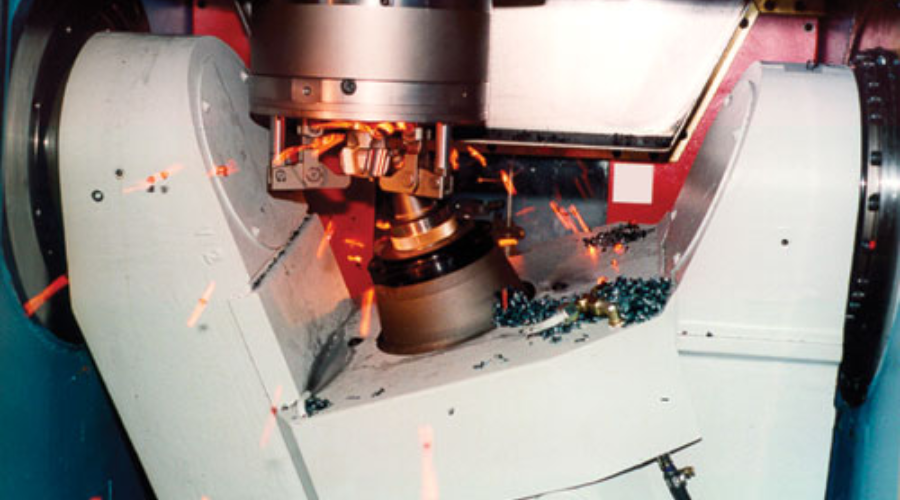

Fuyuancasting

Fuyuancasting is a leading manufacturer and supplier of CNC machines and metal parts. Our cast copper parts are renowned in the marketplace for their durability, precision, and flawless finishes. Place your order with the trusted cast copper parts supplier to get these fantastic parts at affordable rates.

FAQs

What Are Mini Copper Parts, and How Are They Manufactured?

Mini-copper parts refer to small-sized components made of copper that are used in various electronic devices. These parts are typically cast using the process of copper casting, which involves pouring molten copper into molds to create precise and intricate shapes. The casting process allows for producing mini copper parts with high precision and accuracy, which provide ideal choices for compact electronic circuits.

What Advantages Do Mini Copper Parts Offer in Electronics?

Mini copper parts offer several advantages in electronics, including:

Enhanced Connectivity: Mini copper parts enable efficient and reliable connectivity within electronic devices, ensuring smooth data transmission and power delivery.

Space Efficiency: Due to their small size, mini copper parts contribute to the miniaturization of electronic devices, making them more space-efficient and lightweight.

Excellent Electrical Conductivity: Copper's superior electrical conductivity ensures minimal signal loss and low resistance, making it ideal for high-performance electronics.

How Are Mini Copper Parts Used in Mobile Devices?

Mini copper parts, such as smartphones and wearables, are vital in mobile devices. They are used in various components, including microprocessors, memory modules, antennas, and connectors. These mini parts facilitate seamless communication between different device parts, enabling features like high-speed data networks, GPS, Bluetooth, and NFC.

How Do Mini Copper Parts Contribute to the Internet of Things (IoT)?

In the Internet of Things (IoT) realm, mini copper parts enable connectivity among interconnected devices. They are essential in IoT devices, including smart speakers, smart thermostats, and other smart home devices. Mini copper parts ensure efficient communication between IoT devices, enabling them to interact with cloud-based services seamlessly.

Comments